Large Bore Cannon

Mounting The Trigger

Time to take care of that dangling trigger! I wung this part a little more than I usually do.

Based on the cad model, I know that the the distance from the trigger face to the back of the grip will be too long unless I shorten one of the parts. For reference, here’s a very interesting forum post with grip measurements from several handguns. The optimal distance between the back of the grip and the trigger face seems to be about 2.7 inches.

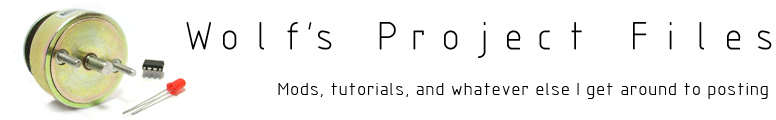

As luck would have it, due to the design of my trigger valve (a dental air valve), it was possible to mill off 1/8″ or so without hitting any of the internals. I lost the threads on the outlet side, but I don’t need those anyway. The brass machined really nicely.

As luck would have it, due to the design of my trigger valve (a dental air valve), it was possible to mill off 1/8″ or so without hitting any of the internals. I lost the threads on the outlet side, but I don’t need those anyway. The brass machined really nicely. Next I machined a little block to mount valve through. I would’ve liked to thread the valve directly into the block, but it has some kind of non-standard threads, so I decided to just use the nut.

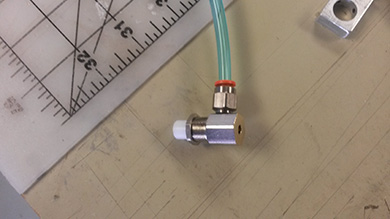

Next I machined a little block to mount valve through. I would’ve liked to thread the valve directly into the block, but it has some kind of non-standard threads, so I decided to just use the nut. First, I drilled the giant hole for the valve. The final drill is shown (i forget the size), but first I hit it with center drill, then a 1/4″.

First, I drilled the giant hole for the valve. The final drill is shown (i forget the size), but first I hit it with center drill, then a 1/4″. Next I drilled and taped the two holes for the mounting screws. I drilled down until the holes were just touching the circumference of the large hole. I only had starting taps on hand, which don’t fully finish the first 4 threads, so I had to make the holes deeper than I would have liked to get enough complete threads for the mounting screws.

Next I drilled and taped the two holes for the mounting screws. I drilled down until the holes were just touching the circumference of the large hole. I only had starting taps on hand, which don’t fully finish the first 4 threads, so I had to make the holes deeper than I would have liked to get enough complete threads for the mounting screws.